Aspect Coatings - Transforming Powder Coating Operations with Creviz End-to End Custom ERP Solution

Key Highlights

Aspect Coatings

In today's fast-paced industrial environment, relying on spreadsheets for production and planning can limit growth. For Aspect Coatings, a leading powder coating company in Bengaluru, this was exactly the challenge - until they discovered how a custom software solution from Creviz could transform their operations.

Creviz, a company specializing in custom application development for manufacturing and service industries, helped Aspect Coatings design a powerful, tailor-made digital system that replaced Excel chaos with a structured, efficient, and intelligent workflow.

The result:

- ✔Streamlined production and material tracking

- ✔Real-time visibility across departments

- ✔Reduced operational errors and downtime

- ✔Smarter financial and inventory management

This is the story of how Aspect Coatings achieved higher productivity and process control through Creviz's custom software development approach.

About Aspect Coatings

Aspect Coatings is a renowned industrial and architectural powder coating facility based in Bengaluru, India. With a monthly processing capacity of over 150 tons of aluminum sections and profiles, the company has earned the trust of major clients like Sobha Developers, DLF etc and other leading builders and fabricators across India.

Aspect Coatings specializes in high-quality powder coating, wood finishing, PVDF coating, and anodizing services. They source premium powders from global brands such as Jotun, AkzoNobel, and Axalta, offering coatings with durability warranties of up to 30 years.

Their core strength lies in custom color matching, precision finishing, and adherence to architectural standards, making them a preferred partner for construction, façade, and industrial projects across India.

The Challenge: Managing Complex Operations in Excel

Despite their strong technical capabilities and experienced team of 50+ employees, Aspect Coatings faced a growing operational challenge.

Like many industrial service providers, they were running all key functions - production tracking, quotation generation, material inward, and financial planning - through Excel spreadsheets.

This approach soon became unsustainable as operations scaled:

- Frequent data errors and duplicate entries across departments

- No real-time production tracking - leading to missed deadlines

- Inefficient planning and scheduling due to lack of visibility

- Delayed customer quotations and order fulfillment

- Difficulty tracking color batches, powder usage, and warranty details

Aspect Coatings explored popular ERP platforms like Zoho and Odoo, but soon realized that off-the-shelf software wasn't designed for the unique workflows of industrial powder coating. The processes involved multiple service types, color combinations, and specialized costing structures - all of which required flexibility that traditional software couldn't provide.

The Turning Point: Partnering with Creviz

Recognizing the need for a custom-built digital solution, Aspect Coatings partnered with Creviz - a leading company known for custom software development for manufacturing and service industries.

The Creviz team spent time studying every detail of Aspect Coatings' processes - from customer enquiry to dispatch - and built a fully tailored application that automated and digitized their end-to-end operations.

Unlike conventional ERP systems, this Creviz custom application was designed specifically for industrial powder coating workflows, providing total control and visibility across departments.

Solutions Implemented

To overcome operational bottlenecks and unify all processes, Creviz implemented a suite of fully integrated modules tailored to Aspect Coatings' exact workflow.

Each solution below highlights how a specific department transitioned from manual Excel-based management to a connected, automated, and insight-driven system - resulting in better accuracy, speed, and collaboration across teams.

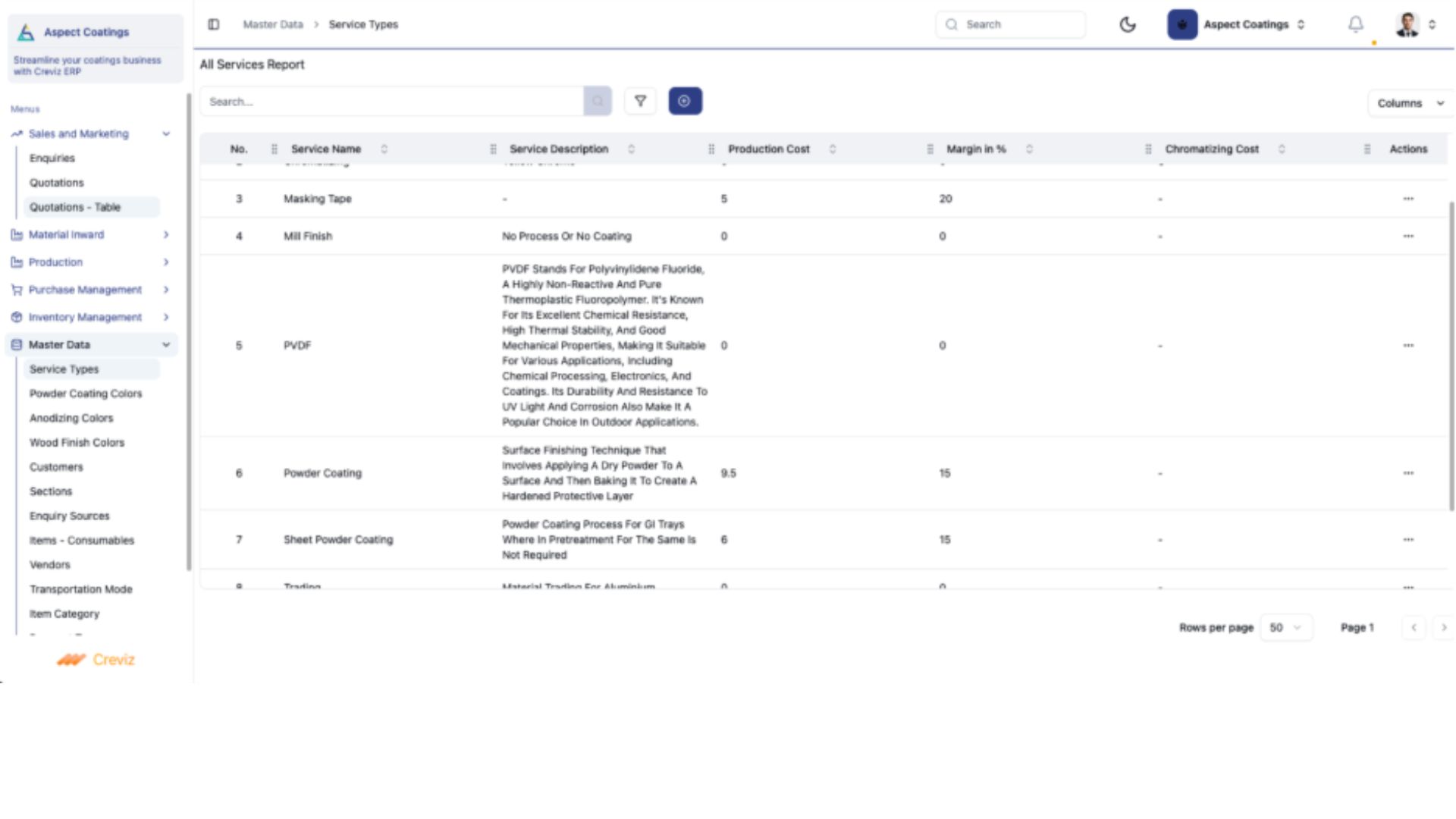

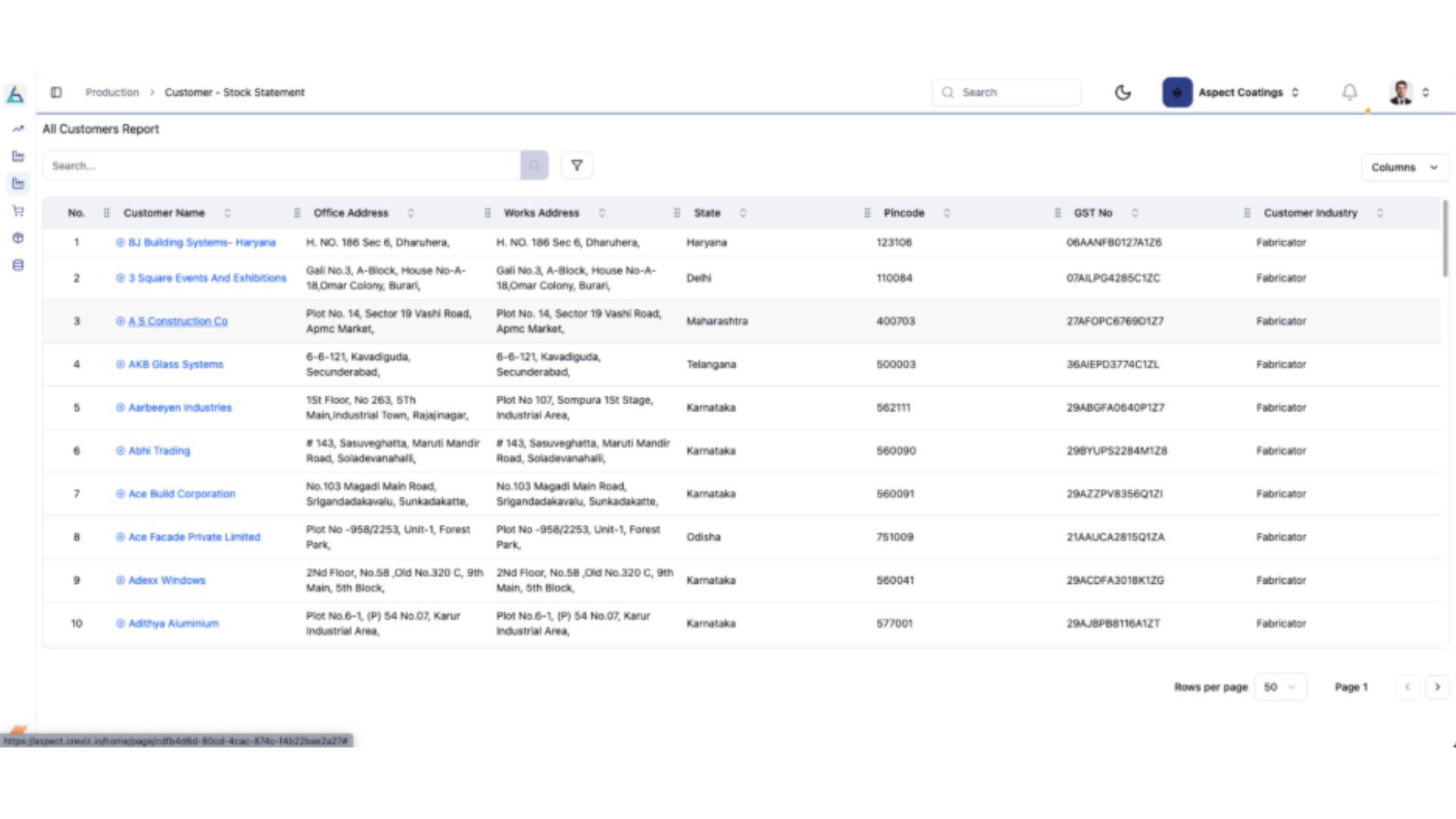

1. Centralized Master Data Management

The foundation of the new system was a robust Master Data Repository - consolidating all business-critical information in one place:

- Service categories such as Powder Coating, Wood Finish, PVDF, Anodizing, and Sheet Coating.

- 500+ RAL colors with different powder manufacturer details, warranty periods, finish types, and price variations.

- 15+ anodizing color and warranty combinations, along with dual-coat and tri-coat PVDF options.

- 20+ Wood finish variants based on film type and shade.

- Customer segmentation (builders, fabricators, industrial clients).

- Vendor and supplier records with product catalogs, pricing history, and quality ratings.

- Profile library of aluminum sections with coverage perimeter, total perimeter, weight per meter, and technical drawings.

Master Data Management System

Centralized repository for all business-critical information including service categories, colors, customers, vendors, and profile libraries

Image preview

This master database ensures every team - from sales to production - worked with the same accurate, real-time data.

"Having all our service types, colors, and pricing data in one master system has removed confusion between teams. Everyone now works with the same, accurate data."

- Al Shariqa, Production Coordinator, Aspect Coatings

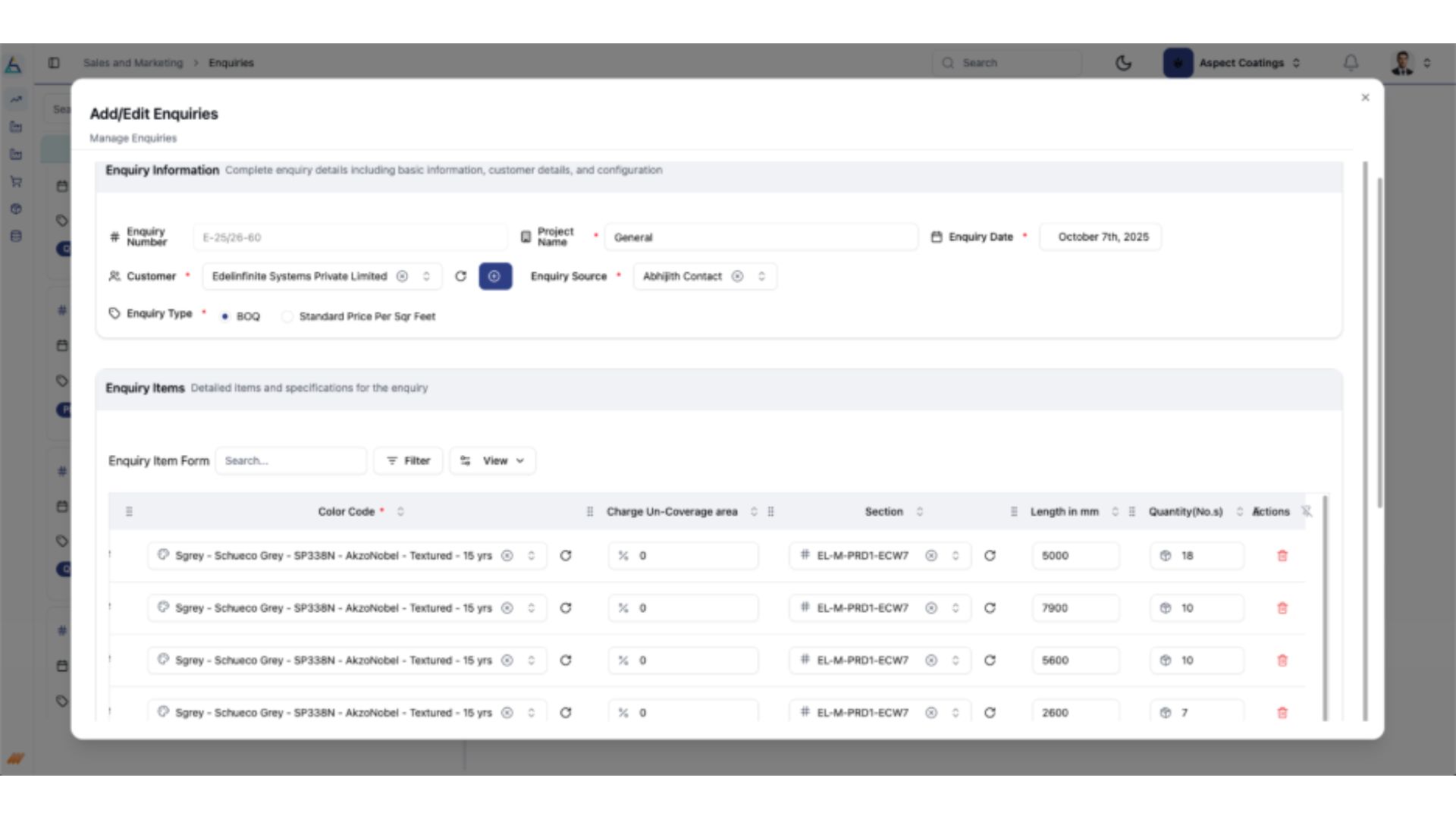

2. Enquiry and Quotation Automation

The custom quotation module built by Creviz is a game changer for Aspect Coatings. It replaced manual pricing and BOQ management with a smart, rule-based system.

Key capabilities included:

- Logging enquiries by customer and source, with complete BOQ (Bill of Quantities) including section numbers, lengths, and types.

- Automatic quotation generation in per kg and per sqft formats.

- Smart pricing formulas that adjust margin, powder coverage, uncoverage area, and sub-processes like masking.

- Dynamic quotation templates for Proforma Invoices (PIs) and detailed price breakdowns.

Enquiry & Quotation Management

Complete BOQ management, automatic quotation generation, smart pricing formulas, and customer communication tracking

Image preview

Now, what used to take hours of Excel calculations could be done in minutes - with zero errors.

"Earlier, generating a quotation meant juggling multiple Excel files. Now it takes less than a minute and customers get instant, error-free quotes."

- Abhishek Kumar, Sales Executive, Aspect Coatings

Explore how Creviz custom Quotation & Invoicing empowers other manufacturers to achieve similar results.

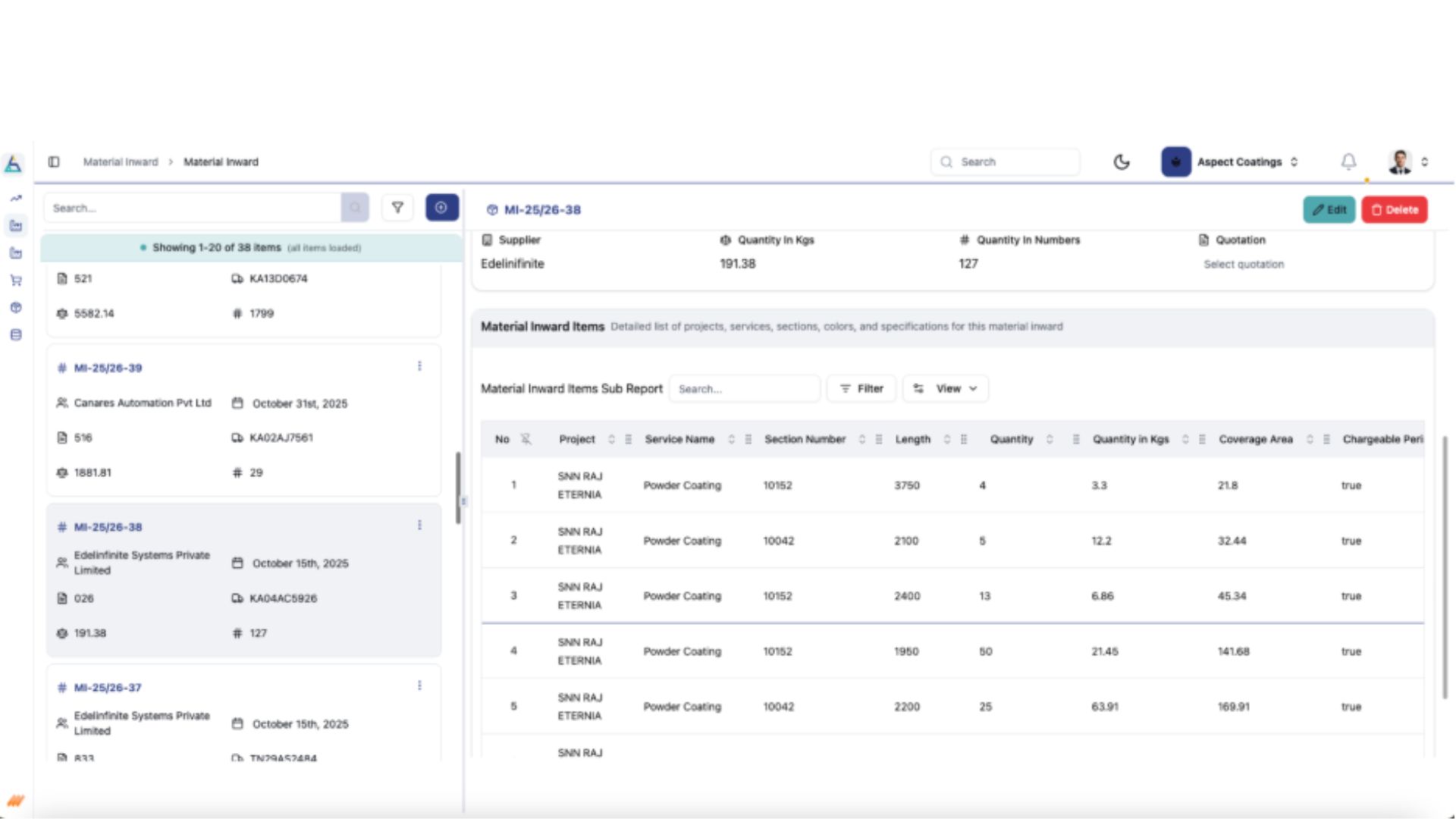

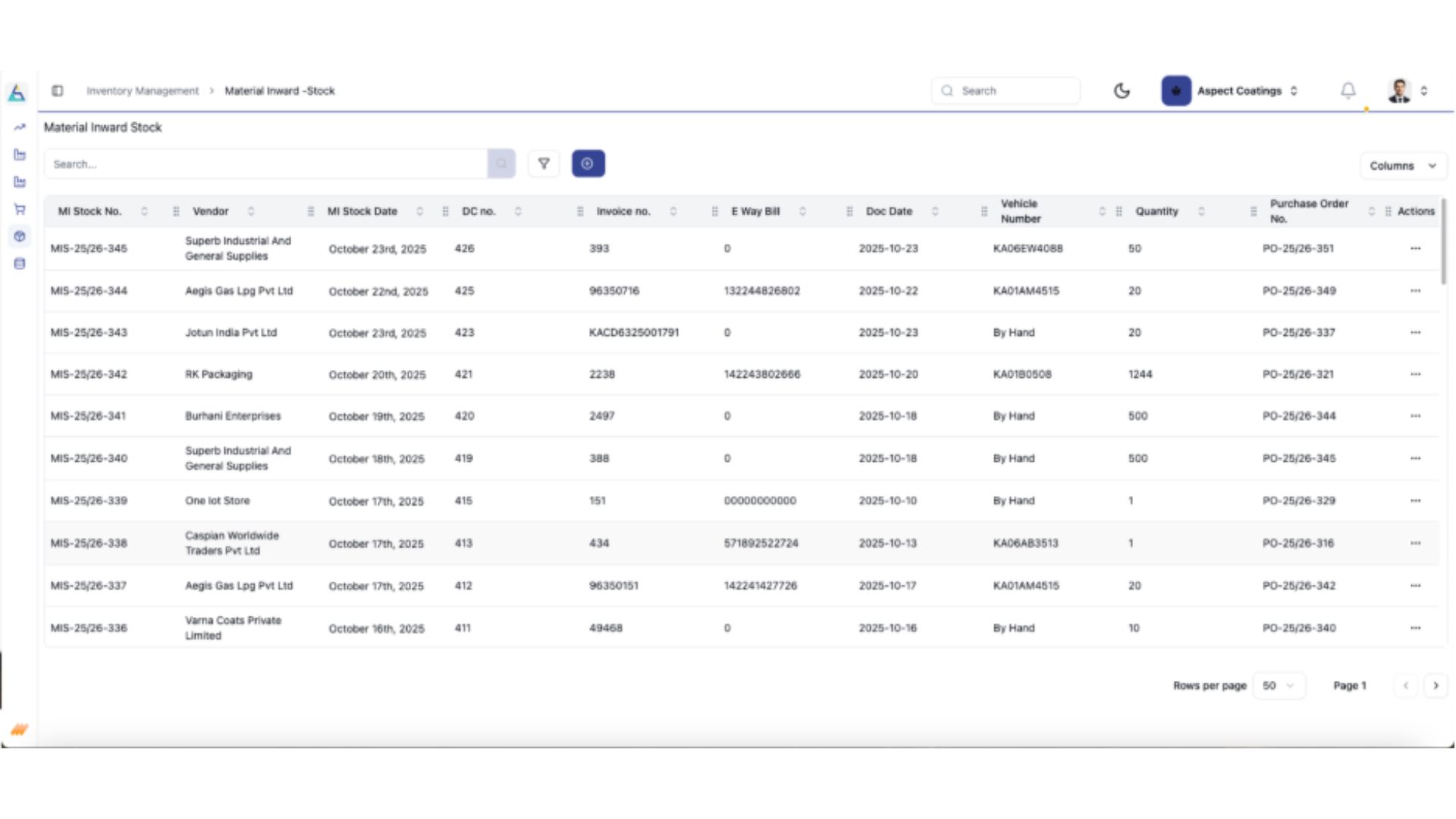

3. Material Inward & Production Planning

One of the biggest operational improvements came from Creviz's production planning and material inward module.

The system allowed Aspect Coatings to:

- Record incoming materials with delivery challans, vehicle details, and supplier/customer data.

- Automatically update stock at every stage - received, pending, processed, packed, and dispatched.

- Sort pending lists by color and customer, optimizing powder changeovers and reducing downtime.

- Predict material availability and visualize plant capacity for upcoming days.

Material Planning & Production Scheduling

Material inward tracking, stock management, production planning interface, capacity visualization, and workload optimization

Image preview

This visibility eliminated manual stock tracking and allowed supervisors to plan workloads efficiently - significantly improving throughput and turnaround times.

"The new system shows us exactly what's pending, what's in process, and what's ready to dispatch. Planning workloads has never been this clear."

- Rizwan Pasha, Planning Supervisor, Aspect Coatings

Learn how Creviz's Production Planning solution enables manufacturers to optimize workflows and replicate these results.

4. Production Execution & Tracking

On the shop floor, the Creviz custom software enabled real-time tracking of every process stage:

- Auto-generated job cards for Powder Coating, Anodizing, PVDF, and other service types.

- Technicians could update processed quantities directly from tablets or terminals.

- Live dashboards display progress for each material inward entry - pending, processed, or packed.

- Raw material usage such as powder, chemicals, tapes, and packaging could be tracked accurately.

Production Execution & Tracking

Real-time shop floor tracking, job card management, technician updates, and live progress monitoring for all coating processes

Image preview

This data-driven tracking minimized errors, improved accountability, and enhanced overall production efficiency.

"We can now monitor every job in real-time from tablets on the floor. The visibility has reduced miscommunication and rework drastically."

- Ashraf, Shop Floor Manager, Aspect Coatings

5. Inventory and Purchase Management

Creviz integrated a smart procurement and inventory system within the application:

- Automated purchase planning based on pending stock requirements.

- Vendor quotation tracking and performance scoring based on delivery speed, quality, and packaging.

- Integrated quality checks and Goods Receipt Notes (GRN) for received items.

- Inventory categorization for consumables, chemicals, and powders with real-time valuation.

Inventory & Purchase Management

Complete inventory tracking, consumables management, automated purchase planning, vendor management, and procurement analytics

Image preview

Aspect Coatings could now see exactly what materials were in stock, what needed ordering, and which vendors were performing best - all in one dashboard.

"Inventory used to be a black box. With Creviz, I can see consumables, powder stocks, and pending GRNs instantly. Reordering is now data-driven."

- Mohan Patel, Procurement Head, Aspect Coatings

See how Creviz's Inventory Management module is driving measurable results for other manufacturing businesses.

6. Financial Management & Reporting

Finally, Creviz linked operational data directly with financial workflows, creating a 360° visibility system:

- Auto-generation of invoices and PIs for executed jobs.

- Tracking of Accounts Receivable (AR) and Accounts Payable (AP) in real time.

- Visibility into payment cycles, pending invoices, and vendor settlements.

- Insightful metrics like AR/AP days for financial health tracking.

By connecting finance with production, Aspect Coatings gained control over its entire business flow - from job creation to cash realization.

"Linking finance with production gives us clarity like never before. I can track invoices, payments, and vendor dues without calling anyone."

- Karthik, Accounts Manager, Aspect Coatings

Results: Tangible Impact in Just Months

After implementing the Creviz custom application, Aspect Coatings experienced a dramatic shift in operational performance:

| Metric | Before Creviz | After Creviz |

|---|---|---|

| Data Entry Errors | Frequent | Reduced by 70% |

| Quotation Turnaround | 2–3 hours | Under 15 minutes |

| Production Planning | Manual, Excel-based | Automated & Visual |

| Powder Change Downtime | High | Reduced by 40% |

| Material Tracking | Fragmented | Real-time, Centralized |

| Financial Visibility | Delayed | Instant Dashboards |

Client Feedback

"Creviz helped us move from spreadsheets to a fully connected digital system built exactly around our workflow. The application has completely transformed how we plan, track, and execute jobs. We now have full visibility into every process - from enquiry to dispatch - all in one place."

- Abhijith P, CEO, Aspect Coatings

Why Custom Software Development Made the Difference

Generic ERP or SaaS products often fail to capture the unique needs of industrial service providers. Powder coating operations like Aspect Coatings require multi-variable costing, color-based scheduling, complex job hierarchies, and real-time tracking - features that simply don't exist in out-of-the-box tools.

Creviz's approach to custom software development ensured:

- The application was built around Aspect's exact operational model.

- Every process - from enquiry to finance - was digitally connected.

- The software could evolve as the business grew.

Unlike conventional ERPs, Creviz's solution offered flexibility, domain fit, and usability, without forcing Aspect Coatings to adapt to a rigid structure.

Conclusion

The collaboration between Aspect Coatings and Creviz showcases the true value of custom application development for industrial and manufacturing businesses.

By replacing Excel-based operations with a tailored digital ecosystem, Aspect Coatings unlocked higher efficiency, faster decision-making, and better customer satisfaction - proving that the right software isn't just about automation, but about alignment with real-world workflows.

Today, Aspect Coatings runs a fully digitized, insight-driven operation - powered by Creviz's custom software platform - setting a new benchmark for how industrial coating companies can scale using technology built precisely for them.